Water Cooled Cables

Reputed Water Cooled Cable Manufacturer In India

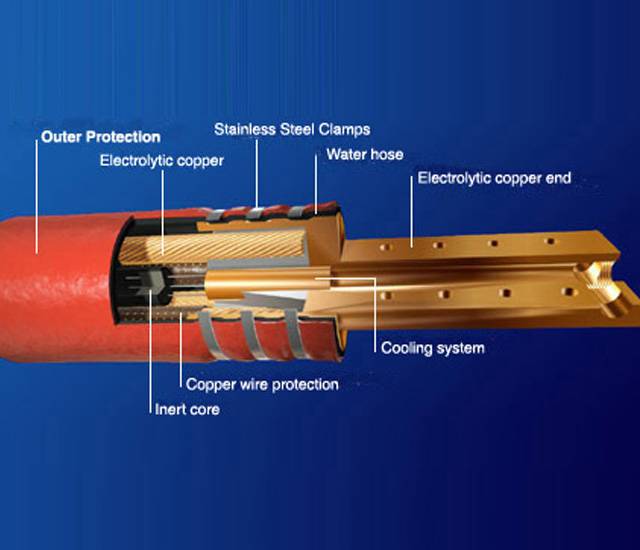

L.D. Bhattar & Co. is the one-stop destination if you are looking for the best water cooled cable manufacturer in India. Water cooled cables are majorly used as a secondary conductor in steelmaking arc furnaces. These cables are designed in such a way that they can sustain radiant heat from the electrodes. Water cooled cables can be used in various extreme conditions involving high temperatures and mechanical external forces.

Main Parameters For The Water Cooled Cables Sizing

There are four primary parameters for the sizing of the water cooled cables. Have a look below to have a brief understanding of them.

● Water cooling flow rate: The water cooling flow rate is determined as per current intensity as well as inlet and outlet temperatures.

● Current density: Do you know what must be the current density in a water-cooled cable? It’s 4,5 A/mm2 for EAF and 5,5 A/mm2 for LF.

● Cable length: Determining cable length enables raising, lowering, and adjusting electrodes.

● Bending radius: Water-cooled cables’ bending radius is nearly five to six times the water hose’s inner diameter.

What Sets Us Apart?

Our team works hard to serve our clients with the best water cooled cables at the best prices. As the leading water cooled cable manufacturer in India, we offer a wide variety of water cooled cables for different uses. These cables are mainly used in the manufacturing of industrial furnaces to supply current to electrodes and heating elements. One of the most important reasons for using water cooled cables is their ability to maintain a stable temperature and avoid furnace overheating.

You can also count on us for repairing or replacement of old cables.

Features of Our Water Cooled Cables

● We use electrolytic grade copper conductors for low energy consumption.

● We use lead-free brass in the end connection which offers more strength.

● We offer maximum power and maintain proper flow and pressure tests.

Got queries about our water cooled cables? Give us a call today.